Metal Control Policy

|

|

|

- Blanche Wilkerson

- 9 years ago

- Views:

Transcription

1 Operated by Metal Control Policy April 2011 Issue 2-1 -

2 The following policy covers: Primark Stores Ltd - Metal Control Policy Section A: - Introduction to metal control: Pages 3-4 Why is metal control important? What areas does metal control cover? What needs to be in place for an effective Metal control policy? What are the consequences of poor metal control to Primark and to you? Section B - How good are your metal control procedures: Page 5 A questionnaire for suppliers/factories to complete to determine how good their existing systems are and to examine the risks Section C - Metal control procedures: Pages 6-7 Needle control Metal tools and trims Metal detection Section D Penalties: Non Compliance: Page 10 Penalties incurred for non compliance of Metal Control Policy within your factory / factories Section E - Example record formats and the Self-Assessment checklist: Pages 11-7 Examples of record sheets for needle and metal detection and a self-assessment checklist for suppliers to determine how well their existing systems are working Section F- Photograph Guide: Pages Photos of good and bad practice from actual factory sites - 2 -

3 Why is metal control important? Section A - An introduction to metal control Primark Stores Ltd have a duty to its customers to provide safe, quality products. This duty is drawn both from our company values and from EU legislation. EU laws stipulate that poor quality and safety of products sold in our stores could result in serious legal action against the company. The Consumer Protection Act 1987 makes it a criminal offence to supply consumer goods that fail to comply with general safety regulations (General Product Safety Regulations 1994). This means that any kind of contamination of our products which poses a risk to our customers safety is completely unacceptable. We have therefore produced this guide regarding safe working practices and procedures for metal control to help you to eliminate the risk of metal contamination. What areas does metal control cover? Needles sewing machine, knitting machine and hand sewing. Kimball gun needles, blades, knives, scissors and other tools for cutting. Any sharp instrument used during production which can cause harm or is serious safety risk All processes that require needles (including storage, issue, use and disposal) need precise control. These policies are not difficult to put in place but rely on clear instruction to and cooperation of all workers, supervisors and managers. Scissors, knives and cutting blades Scissors of all sizes are used in many sections of a factory so they need to be used responsibly. Scissors must be securely attached to work stations or issued and collected at the beginning and end of each day. Cutting room blades, needles and scissors, must be issued and collected at the beginning and ed of each day. Pins, staples, nails and metal components You need to list all the metal items you use in your factory. This should include pins and staples as well as metal components that you might apply to garments during the manufacturing process. Some examples include: poppers in babywear, studs and rivets in denim, and buttons on garments. Examples of situations where trims can provide a risk of metal contamination: Rolls of lace that are secured by pins Brand labels which are attached with safety pins Documents with staples Sub-contracted processes: Embroidery and beading, where adequate controls are not established. Small fasteners like snap fasteners can easily be dropped into pockets or baby grows with enclosed feet. Ensure your quality control inspection includes turning enclosed areas inside out to remove any loose items

4 What needs to be in place for an effective Metal control policy? Having an effective metal control policy requires a number of procedures to be established. A procedure for replacing worn and broken needles: Clear documented procedures that cover all the processes, using all types of needles in your manufacturing sites internal and external. Suggested procedures are provided in this document (see Section C). The control of metal tools and small component parts used in the production process: Clear documented procedures that cover all other areas of risk for metal contamination in your manufacturing sites internal and external. Suggested procedures are provided in this document (see Section C). A metal detection procedure: Clear documented procedures for your methods of detecting metal contamination. Suggested procedures are provided in this document (see Section C). Training of all relevant employees: All workers in the manufacturing unit must be properly trained in order for the metal control policy to be effective. All new staff must be trained on metal control procedures. It must be part of your induction training programme. Management support and constant policing of the procedures: An effective metal control policy requires constant monitoring and checking. This can be done in a number of ways: Cleaning staff to report any sharp metal pieces found during cleaning Regular checks of the production areas on floors, work surfaces and drawers Check record sheets for accuracy or mistakes Periodically carry out the self assessment checklist (provided in this document see Section E) to review the whole process, including external locations if used. All management must be fully committed to initiating these procedures - it is critical to establish them into everyday practice. Metal control policy, must be incorporated into your own internal policies. What are the consequences of poor metal control? The injuries resulting from metal contamination can range from scratches and cuts to fatal injury if bits are swallowed by children. Therefore, we need your commitment to implementing effective procedures in all manufacturing sites used for Primark/Penneys production and maintaining these procedures to the highest standards with constant monitoring and regular, effective training

5 Section B - So how good are your metal control procedures? You may already be running what you consider to be good metal control procedure, in which case this will also satisfy Primark s requirements? You can have good written procedures but are they really working in practice? Staff turnover and daily production pressures can have significant negative impacts on the standards of procedures. We have included a checklist that should be used regularly to test your standards. If you have any negative points from the self assessment checklist then you need to review your procedures and carry out re-training, using this guide to reinforce your factory s standards. The self assessment checklist is available in Section E. Needle Control Section C - Metal control procedures This section provides procedures for a variety of situations involving sewing and knitting needles. Sewing and Knitting Needle Control This needle control policy covers the strict control of all needles to ensure that the only ones in use are for the manufacturing process and that the disposal of all worn or broken needles is carried out by authorised personnel. The only needles allowed at work stations are those currently needed to operate the machine process. No spare needles should be held at machine point. New needles are kept in a locked location only to be accessed by trained, authorised personnel. Worn and damaged needle replacement Needles which are worn or damaged but not broken are to be collected and a new needle must be issued by the authorised personnel. Old needles are to be disposed of into a sealed jar or tin with a small opening in the top. The jar must be kept in the secure location and disposed of responsibly. For manual and automated knitting machine needles, sealed disposal containers can be placed near the machines. The number of worn or damaged needles should be counted and used to update the needle audit report (see Section F)

6 Broken needles When a needle breaks, the operation must be stopped and the supervisor informed. All the needle pieces must be located and checked against a whole needle to make sure all the pieces have been found. The pieces must be immediately attached to the record sheet with clear adhesive tape and fully recorded with all information (see Section F). A new needle may only be issued when it is confirmed that all the needle pieces are found. If all needle pieces cannot be found then the product being worked on and any other work in close proximity must be placed into a bag or box and taken to the isolation area for further checking. The workplace must be checked with a hand-held metal detector or magnet before work restarts. The handheld detector must be calibrated and operating correctly, using the 1.2mm test piece before being used. Check for the missing needle pieces in the isolation area. If found, all the pieces are to be recorded on the record sheet as normal. If not found, the products must be placed in a polythene bag and deposited in the secure reject box ready for disposal later. When the workplace is confirmed as clear, then a new needle can be issued the policy must be one needle out, one needle in. Record sheets should be kept for a minimum of one year. Other situations Machine maintenance Machine operators must remove all needles from the area in and around machines. Machines that are not in use must also be cleared of needles. Embroidery Machine embroidery embellishment must be controlled in the same way as main production processes, whether within your factory or at a sub-contracted specialist unit. Ensure the same procedure is applied and regularly monitored. Sample room The same needle procedures should be implemented in sample rooms. An example of a broken needle record sheet is provided in Section E. Record sheets must be kept for a minimum of one year and be provided for inspection upon request. Hand Sewing Needle Control The issue of hand sewing needles is just as important as control of machine needles. Hand sewing needles are to be issued to necessary workers and logged in a record book. At the end of the work session, or day, the issued hand needles must be returned and accounted for. Hand sewing needles are not to be used as a tool: e.g. removing fabric flaws. Alternative tools must be provided, such as a quick unpick. The issue of such tools should be logged and returned at the end of each working period

7 Kimball gun needles Kimball gun needles need to be controlled and disposed of in the same way as worn and broken sewing machine needles. Metal tools and trims This section covers some of the other metal items in a production environment that are a potential safety risk. This is not a comprehensive list as you may have specialist equipment that is not covered in this document. Ensure that you make a risk assessment of your particular working environment and that you put controls in place that cover all potential problem areas or processes. Blades and knives, scissors and snips Knives, blades, scissors and snips can be used in every area of the factory from cutting rooms to warehouses. For example: A knife that is lost in a shipping carton can result in a bad injury for someone working in the receiving warehouse. All new and used cutting blades for band knives and straight knives must be kept in a locked cupboard with access only by the cutting room supervisor. Records must be kept of new blades in stock, issued blades and returned blades so that every blade is accounted for. Under NO circumstances can old blades be turned into knives for use in the production area. Old blades must be disposed of responsibly on a regular basis. Where knives are needed to open containers, these should have a retractable blade, be numbered and stored at the end of each day in a secure cupboard. Small scissors and snips must be tied to work stations this applies to ALL areas used for cutting, sewing, inspection, pressing, warehouse, etc. Large scissors in the cutting room and sample room are to be numbered and stored in a secure cupboard at the end of each working day. The supervisor responsible for scissors must check all have been returned. Pins and staples A metal-free zone must be applied to all childrens wear production areas. The risk of injury to children is the most serious, as swallowing sharp metal objects can result in serious injury and even death. Pins and staples must not be used anywhere in the production area, including the sample room. Tape and magnets should be used to attach notices to notice boards. Documents issued into the production areas must not use staples to affix samples or extra pages. Plastic clips or tape are possible solutions. Trims (such as rolls of lace) that are secured with pins should be removed before being sent to the production area. Ask suppliers to use alternative methods wherever possible

8 Small metal component parts Rivets, snap poppers, studs and metal buttons need to be controlled in the production area so that loose ones cannot become trapped in pockets or other enclosed parts of the garment. Where it is not possible to automatically feed these items during the attaching process, then work areas must be set up to contain these small metal parts. Work benches with raised sides to prevent small metal components from dropping onto the floor. The issue of trims in smaller manageable containers can help prevent accidental loss of these small sharp metal trims. Poppers (snap fasteners) used in the production of baby garments are very high risk and needs careful control. REMEMBER: One needle issued for one needle returned. Metal Control is EVERYONE s responsibility training is essential. Metal Detection Metal detection is part of the overall Metal Control Policy and must not be viewed as a replacement for an effective needle control policy. Primark Stores Ltd require the following to be placed through a metal detector: ALL children s wear: Children s clothing, accessories and footwear: ALL MUST be 100% metal detected before being packed into cartons. Adult lingerie and underwear, adult nightwear and adult swimwear: ALL MUST be 100% metal detected before being packed into cartons. Adult clothing, such as outer wear, blouses, shirts, trousers etc are not mandatory but if you have a metal detector then it is good practice to use this for all production. This good practice helps maximise the return on this valuable piece of equipment. When used on children s wear, adult lingerie and underwear, adult nightwear and adult swimwear the metal detector should include the following features: A conveyor belt type detector where the garment passes through an aperture of no more than 127mm in height. The conveyor automatically stops and sounds an alarm when metal is detected. The metal detector can detect ferrous metal of 1.2mm. The machine must be located away from other sources with magnetic fields such as clutch break mechanisms in sewing machines and ceiling fans. Ideally this should be recommended by the machine supplier. The position of the detector must allow a direct flow of all products through the machine so that no garments miss this important checking stage. Ideally the metal detection area should be in a separate area between final QC and Packing. No childrens garments or garments requiring metal detection should pass directly to Packing. (See Section F). The machine should only be operated by trained personnel, ideally trained by the machine supplier. The metal detection machine should be serviced by the machine supplier every 6 months. Photographs can be seen in the Photograph Guide in Section F

9 Metal Detection Procedure Calibration Metal detection machines are sensitive instruments and need daily calibration when in use The machine should be calibrated when switched on and then at least 4 times per day. A 1.2mm test piece provided by the machine supplier should be used to test if the machine is detecting correctly. It should be fed through 3 times at the left side, centre and right side of the conveyor belt. If the test piece is not detected then the service engineer must be called in to fix it. If the calibration is successful then the machine can be used for production checking. Each daily calibration must be recorded on a record sheet an example is provided in Section E. Metal detection in production Garments should be packed wherever possible and put on the conveyor one at a time. When successfully passed through the detector, each item can be packed into cartons but should be kept in the quarantine area until the next successful calibration. Only then can the goods be released for shipping. If the detector fails the next calibration then the goods in the quarantine area will need to go through again when the machine is fixed. Any item which fails the metal detection should be taken to a designated inspection area and checked. When the metal piece is found, the garment can be re-checked and only put to stock if it successfully passes through the detector. If the metal piece is not found then the item must be cut up and placed in the secure reject box. A separate record must be kept of metal detection failure - an example is provided in the Section E. Record sheets should be kept for a minimum of one year. REMEMBER Metal detection is part of the control policy and not a replacement for good needle control practices - 9 -

10 Section D - Penalties; Non compliance In the event that a needle or any other sharp or unsafe object is found in a garment, product or shipment, Primark Stores Ltd will take the follow actions. First Offence; The supplier will incur a penalty fine of USD $5000. All of the FACTORIES used by the supplier which are nominated for the production of Primark product will be subject to an immediate and fully comprehensive inspection of all needle and metal control policies and procedures within the factory / factories. The inspection will be at the expense of the supplier. Primark Stores Ltd will nominate the 3rd party company which will carry out the inspection. Time scales for corrections of non compliance with the needle and metal control policy will be agreed accordingly by Primark Stores Ltd. Second Offence; The supplier will incur a penalty fine of USD $5000. All of the FACTORIES used by the supplier which are nominated for the production of Primark product will be subject to an immediate and fully comprehensive inspection of all needle and metal control policies and procedures within the factories. The inspections will be at the expense of the supplier. Primark Stores Ltd will nominate the 3rd party company which will carry out the inspection. Time scales for corrections of non compliance with the needle and metal control policy will be agreed accordingly by Primark Stores Ltd. ALL of the FACTORIES WILL be subject to a further 3rd party inspection to validate agreed improvements. Third Offence; The supplier will incur a penalty fine of USD $5000. Primark Stores Ltd will no longer permit the use of the factory / factories which continue to fail to comply to Primark s Metal Control Policy. These factories will be DIS-ENGAGED

11 SECTION E Self Assessment Checklist for Metal Control Standards Factory name and location Subcontractor Assessed Site Details Own facility Areas checked Yes No Summary of findings Sample Room Cutting / parts preparation Weaving/Knitting Assembly/sewing Finishing Packing Specialist process/machinery Overall standard acceptable? Checklist for Metal Control Standards Needles/Scissors/Metal items in general Ref Check Point YES NO Comments N1 Is there a secure location for keeping needles? N2 Is there a secure location for keeping other metal items? N3 Is there a trained, authorised person to issue needles or other metal tools? Name : N4 Do the authorised people fully understand the procedure? N5 Is there a needle record sheet for broken needles? N6 Is it correctly and accurately completed? N7 Are all broken needles included on the record sheet? N8 Do workers understand the metal control procedure in this area? N9 Is there a clear procedure for dealing with missing broken needle pieces? N10 Are there any spare needles at the machines? N11 N12 N13 N14 N15 N16 Are there any broken needles on the floor? Are there any untied small scissors at machines? Are there any old cutting blades being used as knives? Are there any other sharp metal items in the work area? Has training been given to personnel for Metal Control? Are there pins or staples used in this area? Detail : Date of last training :

12 SECTION E Self Assessment Checklist for Metal Control Standards Checklist for Metal Control Standards Metal Detection Ref Check Point YES NO Comments MD1 Is the metal detector located so all items pass through without being missed? MD2 Has the metal detector been serviced in the past 6 months? Last date of service : MD3 Does the metal detector only detect nonferrous metal? MD4 Is the machine operator trained to use the machine? Date trained : MD5 Does the operator have a good knowledge of the working procedures? MD6 Is the machine calibrated when in use? How many times per day : MD7 Is there a test piece used for calibration? Size of calibration piece : MD8 Is a record kept of each calibration? MD9 Is the production passed through the metal detector isolated until the next calibration? MD10 Is a record kept of the number of items metal detected? MD11 If metal is detected, does the conveyor stop and an alarm sound? MD12 Is there a record sheet for metal pieces found? MD13 Is the machine restarted by a key? Who has the key? MD14 Is there an isolation box for items where the metal contamination cannot be found? Additional observations Assessed by name/company/position Signature and date

13 SECTION E Broken needle record sheet - EXAMPLE ONLY Date 25/05/ /05/2009 Style number / Customer 1234/Good Designs 1234/Good designs Needle Type Machine number Operator name Actual needle pieces Overlock 2788 J.Jones Stick needle pieces here Lockstitch 2533 L.Baker Stick needle pieces here Put through metal detector and pieces found All needle parts found? Yes / No If no, action taken Signature Signature of responsible person Signature of responsible person 13

14 SECTION E Needle Stock Record Sheet EXAMPLE ONLY Date Needle Type Issued to : Area Issued to : Name Number of needles in stock Number of needles issued New balance of needles in stock Signature 25/05/2009 Blind Hem Sewing line 2 P.Smith Signature of responsible person 14

15 SECTION E Daily Machine calibration record Date: EXAMPLE ONLY Time Pass Fail Operator Name Signature 9am 3 x test OK J.Smith Signature of trained person This form is to be used to record one full day of production passed through the metal detector. Use a new form at the start of each new day 15

16 SECTION E Garments metal detected - record sheet EXAMPLE ONLY Date Time- To/from Worker name Item description Style Number Order number No. Passed No. Failed Signature 25/05/2009 9am to 11am J.Smith Print top 1234 PO Signature of operator 16

17 Date Time Operator name 25/05/ pm J.Smith Print top 25/05/2009 4pm J.Smith Print top SECTION E Metal detected record sheet EXAMPLE ONLY Item description Style No./ Order No. What was found? Location of object and action Signature 1234/PO Needle piece Neck seam/removed Operator signature 1234/PO Not found Item placed in reject bin Operator signature 17

18 SECTION F Photograph Guide Conveyor belt metal detector well positioned into a secure isolation area CORRECT PRACTICE 18

19 Section F- Photograph Guide Conveyor type detector placed at the end of the packing area and with some simple barriers can ensure all goods go through the process. This model has an automatic recording system. CORRECT PRACTICE 19

20 Section F- Photograph Guide Secure disposal for items which fail the metal detector process CORRECT PRACTICE 20

21 Section F- Photograph Guide Incorrect positioning with no natural flow from the packing section and no record keeping a rarely used valuable asset X INCORRECT PRACTICE 21

22 Section F- Photograph Guide Small scissors tied to workplace CORRECT PRACTICE 22

23 Section F- Photograph Guide Band knife blade left in the work place. Should be kept in a secure location X INCORRECT PRACTICE 23

24 Section F- Photograph Guide Scissors not secured to workplace and screw driver not stored in designated area X INCORRECT PRACTICE 24

25 Section F- Photograph Guide QC small scissors attached to work bench CORRECT PRACTICE 25

26 Section F- Photograph Guide Lip around work bench for containing small metal trims CORRECT PRACTICE 26

27 Section F- Photograph Guide Clear information about metal free areas CORRECT PRACTICE 27

FOREIGN MATTER MANAGEMENT 36 QUESTION ASSESSMENT

Name: Employee I.D. or Personal I.D. Number: Company Name: Department: Head of Department: I understand that this 36 question test proves that I know what I am doing and therefore gives me no reason whatsoever

Name: Employee I.D. or Personal I.D. Number: Company Name: Department: Head of Department: I understand that this 36 question test proves that I know what I am doing and therefore gives me no reason whatsoever

The Jeans Collection

The Jeans Collection Video 4 - Cutting out the panels The tools that you will need to cut out your cloth: 1. Commercial jeans pattern 1. Measurement sheet 2. Tailors chalk. 3. Tape measure 4. Pattern cutting

The Jeans Collection Video 4 - Cutting out the panels The tools that you will need to cut out your cloth: 1. Commercial jeans pattern 1. Measurement sheet 2. Tailors chalk. 3. Tape measure 4. Pattern cutting

Kids Woven - Minimum Construction Standards

Kids Woven - Minimum Construction Standards NOTE All construction standards will be followed except when specified otherwise Must use Bon-Ton approved suppliers Vendor must meet all applicable Bon-Ton

Kids Woven - Minimum Construction Standards NOTE All construction standards will be followed except when specified otherwise Must use Bon-Ton approved suppliers Vendor must meet all applicable Bon-Ton

Example ESD Control Program Document Based on ANSI/ESD S20.20-2007

PROFESSIONAL STATIC CONTROL SERVICES Example ESD Control Program Document Based on ANSI/ESD S20.20-2007 The following document demonstrates the structure for an ESD control program that is compliant to

PROFESSIONAL STATIC CONTROL SERVICES Example ESD Control Program Document Based on ANSI/ESD S20.20-2007 The following document demonstrates the structure for an ESD control program that is compliant to

Machine Guarding and Operator Safety. Leader Guide and Quiz

4646 Machine Guarding and Operator Safety Leader Guide and Quiz Leader s Guide MACHINE GUARDING & OPERATOR SAFETY INTRODUCTION: A brief description of the program and the subject that it addresses. This

4646 Machine Guarding and Operator Safety Leader Guide and Quiz Leader s Guide MACHINE GUARDING & OPERATOR SAFETY INTRODUCTION: A brief description of the program and the subject that it addresses. This

Outdoor Clothing Buying guide

Outdoor Clothing Buying guide This Outdoor Clothing buying guide has been developed by Muddy Faces to help practitioners purchase effective outdoor clothing on a range of different budgets. This guide

Outdoor Clothing Buying guide This Outdoor Clothing buying guide has been developed by Muddy Faces to help practitioners purchase effective outdoor clothing on a range of different budgets. This guide

HEALTH AND SAFETY IN THE FOOD INDUSTRY DETECTING HARMFUL MICROORGANISMS HEALTH AND SAFETY PRECAUTIONS (EXAMPLES FROM CONQUEST FOODS)

HEALTH AND SAFETY IN THE FOOD INDUSTRY DETECTING HARMFUL MICROORGANISMS HEALTH AND SAFETY PRECAUTIONS (EXAMPLES FROM CONQUEST FOODS) Relevant to: Applied Science Unit 1 Identifying biological hazards Carrying

HEALTH AND SAFETY IN THE FOOD INDUSTRY DETECTING HARMFUL MICROORGANISMS HEALTH AND SAFETY PRECAUTIONS (EXAMPLES FROM CONQUEST FOODS) Relevant to: Applied Science Unit 1 Identifying biological hazards Carrying

ASTCCR2 - SQA Unit Code H548 04 Carry out and complete clean-room cleaning operations

Carry out and complete clean-room cleaning Overview 1 Carry out clean-room 2 Remove and store equipment, tools and materials after clean-room 3 Remove and dispose of contaminated material after clean-room

Carry out and complete clean-room cleaning Overview 1 Carry out clean-room 2 Remove and store equipment, tools and materials after clean-room 3 Remove and dispose of contaminated material after clean-room

Preventative Maintenance Policy

Section 7 - Preventative Maintenance Preventative Maintenance Policy It is the Company Policy of to ensure that all equipment, vehicles, and tools are properly maintained in a condition that will maximize

Section 7 - Preventative Maintenance Preventative Maintenance Policy It is the Company Policy of to ensure that all equipment, vehicles, and tools are properly maintained in a condition that will maximize

Basement Window Installation Guide Hopper and Sliding

Basement Window Installation Guide Hopper and Sliding americancraftsmanwindows.com Project Requirements: Installation must comply with all applicable building codes. Existing window frame, wall and weatherresistant

Basement Window Installation Guide Hopper and Sliding americancraftsmanwindows.com Project Requirements: Installation must comply with all applicable building codes. Existing window frame, wall and weatherresistant

Your Guide to Age Related Sales Trading Standards & Licensing Enforcement

Your Guide to Age Related Sales Trading Standards & Licensing Enforcement Information For Staff Off Licensed Premises This training resource pack has been designed to assist those working in premises that

Your Guide to Age Related Sales Trading Standards & Licensing Enforcement Information For Staff Off Licensed Premises This training resource pack has been designed to assist those working in premises that

Policy for the Management of Asbestos in Buildings

in Buildings Health and Safety Services 1 A1. Introduction If asbestos fibres enter the lungs they can cause cancer or incurable disease. Consequently the University is committed to ensure that all reasonably

in Buildings Health and Safety Services 1 A1. Introduction If asbestos fibres enter the lungs they can cause cancer or incurable disease. Consequently the University is committed to ensure that all reasonably

apparel software garment textile software inventory software warehouse management software order management system logistic software export

apparel software garment textile software inventory software warehouse management software order management system logistic software export documentation software textile software costing software sampling

apparel software garment textile software inventory software warehouse management software order management system logistic software export documentation software textile software costing software sampling

- 2 - IMPORTANT SAFETY REMINDERS

USER MANUAL IMPORTANT SAFETY REMINDERS This appliance should only be used for domestic cleaning, as described in this user guide. Please ensure that this guide is fully understood before operating the

USER MANUAL IMPORTANT SAFETY REMINDERS This appliance should only be used for domestic cleaning, as described in this user guide. Please ensure that this guide is fully understood before operating the

SCION tc 2005 - DASH APPLIQUE Preparation

Preparation Part Number: PTS10-21051 Kit Contents Item # Quantity Reqd. Description 1 1 HVAC Center Vent Trim 2 1 Radio Cover Assy (2 pieces) 3 1 HVAC Control Panel (3 pieces) 4 1 Shift Surround 5 1 Driver

Preparation Part Number: PTS10-21051 Kit Contents Item # Quantity Reqd. Description 1 1 HVAC Center Vent Trim 2 1 Radio Cover Assy (2 pieces) 3 1 HVAC Control Panel (3 pieces) 4 1 Shift Surround 5 1 Driver

Machine/Woodworking Shop The Basic Rules

Machine/Woodworking Shop The Basic Rules 1. Eye protection or face shields are required when working in the shop. A selection of protective goggles and safety glasses are available in the shop. The eyeglasses

Machine/Woodworking Shop The Basic Rules 1. Eye protection or face shields are required when working in the shop. A selection of protective goggles and safety glasses are available in the shop. The eyeglasses

MACHINERY GUARDING. Your Practical Guide

MACHINERY GUARDING Your Practical Guide WELCOME TO AXA Introducing AXA One of the world s largest insurers With more than 50 million customers across the globe, AXA is one of the world s largest financial

MACHINERY GUARDING Your Practical Guide WELCOME TO AXA Introducing AXA One of the world s largest insurers With more than 50 million customers across the globe, AXA is one of the world s largest financial

How To Work With Beads. By Rowan

R O W A N How To Work With Beads By Rowan HOW TO WORK WITH BEADS Adding beads to a knitted or crocheted design gives it a really special touch especially when the beads added are as stunning as those in

R O W A N How To Work With Beads By Rowan HOW TO WORK WITH BEADS Adding beads to a knitted or crocheted design gives it a really special touch especially when the beads added are as stunning as those in

Notes. Material 1. Tools the employee is expected to operate

OSHA Standard29 CFR 1910.211-.247, Subpart O, Machinery and Machine Guarding, and Subpart P, Hand and Portable-Powered Tools and other Hand- Held Equipment. Hand Tool Safety Preparation 1. Read Applicable

OSHA Standard29 CFR 1910.211-.247, Subpart O, Machinery and Machine Guarding, and Subpart P, Hand and Portable-Powered Tools and other Hand- Held Equipment. Hand Tool Safety Preparation 1. Read Applicable

Portable cots, bouncers, & change tables Safety Checklist

Portable cots, bouncers, & change tables Safety Checklist St Kilda Mums check all donated portable cots, bouncers, nappy change tables and other nursery products to access their suitability for re-homing.

Portable cots, bouncers, & change tables Safety Checklist St Kilda Mums check all donated portable cots, bouncers, nappy change tables and other nursery products to access their suitability for re-homing.

SEWING MAINTENANCE CHECKLIST

SEWING MAINTENANCE CHECKLIST Many Retail, Brand-name Marketing, Mail Order and Sourcing Companies are visiting existing and potential Contractor sewing facilities and evaluating their sewing capabilities

SEWING MAINTENANCE CHECKLIST Many Retail, Brand-name Marketing, Mail Order and Sourcing Companies are visiting existing and potential Contractor sewing facilities and evaluating their sewing capabilities

October Safety Subject

October Safety Subject Electrical Hazards All electrical equipment should be kept in good repair. Replace defective equipment or have it repaired by a qualified person. Watch for wiring on appliances that

October Safety Subject Electrical Hazards All electrical equipment should be kept in good repair. Replace defective equipment or have it repaired by a qualified person. Watch for wiring on appliances that

BRC Food Safety Management System Implementation Workbook

We have written this workbook to assist in the implementation of your BRC food safety management system. The workbook is divided into 8 steps that are designed to assist you in implementing your food safety

We have written this workbook to assist in the implementation of your BRC food safety management system. The workbook is divided into 8 steps that are designed to assist you in implementing your food safety

School of Engineering University of Glasgow

School of Engineering University of Glasgow Electronics Workshops Rankine Building 319A (2 Technicians) 510 (1 Technician) 712A (4 Technicians, 1 Modern Apprentice) James Watt South 619 (2 Technicians)

School of Engineering University of Glasgow Electronics Workshops Rankine Building 319A (2 Technicians) 510 (1 Technician) 712A (4 Technicians, 1 Modern Apprentice) James Watt South 619 (2 Technicians)

Waste Services Collection Service

Waste Services Collection Service SSOW 03 - Safe System of Work: Waste Collection D DATE ISSUED: June 2013 PREVIOUS REVIEWS: November 2002, April 2010, June 2011, October 2015 ISSUED BY: Mick Wallis, Collections

Waste Services Collection Service SSOW 03 - Safe System of Work: Waste Collection D DATE ISSUED: June 2013 PREVIOUS REVIEWS: November 2002, April 2010, June 2011, October 2015 ISSUED BY: Mick Wallis, Collections

Fire Safety Risk Assessment Checklist for Residential Care Premises

Checklist for Residential Care Premises Name of Premises: Address of Premises: Name of Responsible Person: What area / location does the assessment cover? Does the assessment cover the whole site YES or

Checklist for Residential Care Premises Name of Premises: Address of Premises: Name of Responsible Person: What area / location does the assessment cover? Does the assessment cover the whole site YES or

If you are planning to use the needle and thread approach, you will need the following supplies:

How to Sew Buttons on Pants for Suspenders You ve decided you d like to wear button- on suspenders either for everyday casual or business wear or for a special occasion. Now all you need to do is make

How to Sew Buttons on Pants for Suspenders You ve decided you d like to wear button- on suspenders either for everyday casual or business wear or for a special occasion. Now all you need to do is make

INSTALLATION INSTRUCTIONS IMPERVIA (Vent and Fixed) AWNING, CASEMENT, and LARGE AWNING WINDOW WITH FINS

2009 Pella Corporation INSTALLATION INSTRUCTIONS IMPERVIA (Vent and Fixed) AWNING, CASEMENT, and LARGE AWNING WINDOW WITH FINS Part Number: 80WH0100 Installation Instructions for Typical Wood Frame Construction.

2009 Pella Corporation INSTALLATION INSTRUCTIONS IMPERVIA (Vent and Fixed) AWNING, CASEMENT, and LARGE AWNING WINDOW WITH FINS Part Number: 80WH0100 Installation Instructions for Typical Wood Frame Construction.

Fire safety advice for landlords

YOU CAN PREVENT IT Fire safety advice for landlords Introduction Each year there are over 50,000 fires in dwellings in the UK. These result in around 300 hundred fatalities and several thousand serious

YOU CAN PREVENT IT Fire safety advice for landlords Introduction Each year there are over 50,000 fires in dwellings in the UK. These result in around 300 hundred fatalities and several thousand serious

UNCONTROLLED COPY FOR REFERENCE ONLY

CLOVER MACHINE AND MFG. 800 MATHEW ST. #101 SANTA CLARA, CA 95050 727-3380 727-7015 fax REVISION: DATE: PAGE 1 OF 45 QUALITY POLICY MANUAL DISTRIBUTION LIST: President Purchasing Manager Vice President

CLOVER MACHINE AND MFG. 800 MATHEW ST. #101 SANTA CLARA, CA 95050 727-3380 727-7015 fax REVISION: DATE: PAGE 1 OF 45 QUALITY POLICY MANUAL DISTRIBUTION LIST: President Purchasing Manager Vice President

Glass & Hard Plastic Control

Safefood 360 provides food safety management software for industry leading food processing plants WHITEPAPER Glass & Hard Plastic Control CONTENTS QUICK SUMMARY 1 Effective Glass and Hard Plastic Control

Safefood 360 provides food safety management software for industry leading food processing plants WHITEPAPER Glass & Hard Plastic Control CONTENTS QUICK SUMMARY 1 Effective Glass and Hard Plastic Control

INFECTION CONTROL POLICY

INFECTION CONTROL POLICY Infection control is the name given to a wide range of policies, procedures and techniques intended to prevent the spread of infectious diseases amongst staff and service users.

INFECTION CONTROL POLICY Infection control is the name given to a wide range of policies, procedures and techniques intended to prevent the spread of infectious diseases amongst staff and service users.

Health and Safety Policy and Procedures

Health and Safety Policy and Procedures Health & Safety Policy & Procedures Contents s REVISION AND AMENDMENT RECORD : Summary of Change Whole Policy 4.0 05 Nov 08 Complete re-issue Whole Policy 4.1 10

Health and Safety Policy and Procedures Health & Safety Policy & Procedures Contents s REVISION AND AMENDMENT RECORD : Summary of Change Whole Policy 4.0 05 Nov 08 Complete re-issue Whole Policy 4.1 10

Chapter 2 EDI TECHNOLOGY

Chapter 2 EDI TECHNOLOGY DL Group is committed to supporting the Universal Product Code (UPC), Electronic Data Interchange (EDI), Voluntary Interindustry Commerce Standards (VICS) and the Uniform Code

Chapter 2 EDI TECHNOLOGY DL Group is committed to supporting the Universal Product Code (UPC), Electronic Data Interchange (EDI), Voluntary Interindustry Commerce Standards (VICS) and the Uniform Code

POP Pushchair. Instructions

POP Pushchair Instructions Important: Keep for future reference Please read these instructions carefully before using your new pushchair Keep them in a safe place so that you may use them in the future

POP Pushchair Instructions Important: Keep for future reference Please read these instructions carefully before using your new pushchair Keep them in a safe place so that you may use them in the future

Portable Grinder. Given a properly adjusted portable grinder, instruction and demonstration of use, each student will be able to:

Portable Grinder I. Competencies Given a properly adjusted portable grinder, instruction and demonstration of use, each student will be able to: A. Identify the major parts of the portable grinder. B.

Portable Grinder I. Competencies Given a properly adjusted portable grinder, instruction and demonstration of use, each student will be able to: A. Identify the major parts of the portable grinder. B.

Warehousing and storage Keep it safe

Warehousing and storage Keep it safe This short guide is to help those involved in warehousing and storage to reduce the number of injuries and cases of occupational ill health. It contains simple advice

Warehousing and storage Keep it safe This short guide is to help those involved in warehousing and storage to reduce the number of injuries and cases of occupational ill health. It contains simple advice

Daycare and Nursery Equipment Safety

Daycare and Nursery Equipment Safety There are hundreds of types of nursery equipment on the market intended to be used with children. However, many of these products are used incorrectly, poorly designed,

Daycare and Nursery Equipment Safety There are hundreds of types of nursery equipment on the market intended to be used with children. However, many of these products are used incorrectly, poorly designed,

INSTALLATION RECOMMENDATIONS. Outdoor Rubber Tiles

INSTALLATION RECOMMENDATIONS Outdoor Rubber Tiles Prior to Installation: The Outdoor Rubber Tiles and accessory transition pieces intended for this installation have been shipped to you via a freight carrier

INSTALLATION RECOMMENDATIONS Outdoor Rubber Tiles Prior to Installation: The Outdoor Rubber Tiles and accessory transition pieces intended for this installation have been shipped to you via a freight carrier

BRC Food Safety and Quality Management System. New Issue 7

New Issue 7 This is an ideal package for Food Manufacturers looking to meet BRC Global Standard for Food Safety (Issue 7 2015) for Food Safety Quality Management Systems. Our BRC Food Safety Quality Management

New Issue 7 This is an ideal package for Food Manufacturers looking to meet BRC Global Standard for Food Safety (Issue 7 2015) for Food Safety Quality Management Systems. Our BRC Food Safety Quality Management

AZEK Rail Install Guide

TRIM MOULDING DECK PORCH RAIL PAVERS AZEK Rail Install Guide Installing AZEK Rail with CableRail by Feeney... 1 Installing CableRail by Feeney for AZEK Rail... 7 Installing AZEK Rail Stairs with CableRail

TRIM MOULDING DECK PORCH RAIL PAVERS AZEK Rail Install Guide Installing AZEK Rail with CableRail by Feeney... 1 Installing CableRail by Feeney for AZEK Rail... 7 Installing AZEK Rail Stairs with CableRail

Window Installation Instructions

Caution The correct installation methods of windows in full frame or insert applications is critical towards achieving the tested performance of the window and longterm enjoyment and energy savings for

Caution The correct installation methods of windows in full frame or insert applications is critical towards achieving the tested performance of the window and longterm enjoyment and energy savings for

Machine and Power Tool Safety Checklist. Version 1.0 June 2011. 3160 Chestnut Street, Suite 400, Philadelphia, PA 19104 215-898-4453

Machine and Power Tool Safety Checklist Version 1.0 June 2011 3160 Chestnut Street, Suite 400, Philadelphia, PA 19104 215-898-4453 Machine and Power Tool Safety Checklist Overview The purpose of this checklist

Machine and Power Tool Safety Checklist Version 1.0 June 2011 3160 Chestnut Street, Suite 400, Philadelphia, PA 19104 215-898-4453 Machine and Power Tool Safety Checklist Overview The purpose of this checklist

All seam allowances are 1/2 unless otherwise noted. All pattern pieces include the seam allowance. Please read all instructions before beginning.

This structured bag has lots of pretty detailing. It s large enough to carry all of your essentials as well. Make it in a great patchwork, or stick to a single fabric! All seam allowances are 1/2 unless

This structured bag has lots of pretty detailing. It s large enough to carry all of your essentials as well. Make it in a great patchwork, or stick to a single fabric! All seam allowances are 1/2 unless

Instructions for Using the Watch Works Tool Kit to Change a Watch Battery

Instructions for Using the Watch Works Tool Kit to Change a Watch Battery Click on this link http://www.allamericanwatches.com/site/626101/product/e2306-a to purchase the Watch Battery Replacement Tool

Instructions for Using the Watch Works Tool Kit to Change a Watch Battery Click on this link http://www.allamericanwatches.com/site/626101/product/e2306-a to purchase the Watch Battery Replacement Tool

Bydureon 2 mg powder and solvent for prolonged-release suspension for injection in pre-filled pen How to use Bydureon pre-filled pen

INSTRUCTIONS FOR THE USER Read these instructions carefully before use Bydureon 2 mg powder and solvent for prolonged-release suspension for injection in pre-filled pen How to use Bydureon pre-filled pen

INSTRUCTIONS FOR THE USER Read these instructions carefully before use Bydureon 2 mg powder and solvent for prolonged-release suspension for injection in pre-filled pen How to use Bydureon pre-filled pen

Triple Threat 3-in-1 Game Table 3 IN 1 GAME TABLE

NG0M Triple Threat 3-in- Game Table 3 IN GAME TABLE Thank 3 in Y Game Table Thank you for your purchase of our product. We work around the clock and around the globe to ensure that our products maintain

NG0M Triple Threat 3-in- Game Table 3 IN GAME TABLE Thank 3 in Y Game Table Thank you for your purchase of our product. We work around the clock and around the globe to ensure that our products maintain

LOCKOUT GUIDELINE. To ensure that a piece of equipment cannot be turned on, pressurized or switched on accidently while an employee is working on it.

Background LOCKOUT GUIDELINE Both Aspasa in its ISHE (Initiating Safety Health & Education) program and Sarma in its SHREQ (Safety, Health, Road Transport, Environment & Quality) program have seen that

Background LOCKOUT GUIDELINE Both Aspasa in its ISHE (Initiating Safety Health & Education) program and Sarma in its SHREQ (Safety, Health, Road Transport, Environment & Quality) program have seen that

FRONT BUMPER INSTALLATION INSTRUCTIONS 2007-2011 DODGE / MERCEDES SPRINTER

Aluminess Products Inc 9402 Wheatlands Ct. #A Santee, CA 92071 619-449-9930 FRONT BUMPER INSTALLATION INSTRUCTIONS 2007-2011 DODGE / MERCEDES SPRINTER Please read before beginning Stainless steel hardware

Aluminess Products Inc 9402 Wheatlands Ct. #A Santee, CA 92071 619-449-9930 FRONT BUMPER INSTALLATION INSTRUCTIONS 2007-2011 DODGE / MERCEDES SPRINTER Please read before beginning Stainless steel hardware

MOHAMMADI GROUP LIMITED

MOHAMMADI GROUP LIMITED (a company of Mohammadi Group) COMPANY PROFILE Mohammadi Group Ltd, a name well known in the Garments Family for its quality manufacturing, styling accuracy, timely delivery and

MOHAMMADI GROUP LIMITED (a company of Mohammadi Group) COMPANY PROFILE Mohammadi Group Ltd, a name well known in the Garments Family for its quality manufacturing, styling accuracy, timely delivery and

F.A.C.E. INVESTIGATION REPORT

F.A.C.E. INVESTIGATION REPORT Fatality Assessment and Control Evaluation Project FACE #94-NJ-009-01 Foreman Crushed to Death After Being Caught in a Screw Conveyor New Jersey Department of Health and Senior

F.A.C.E. INVESTIGATION REPORT Fatality Assessment and Control Evaluation Project FACE #94-NJ-009-01 Foreman Crushed to Death After Being Caught in a Screw Conveyor New Jersey Department of Health and Senior

50 TO 60 INSTALLATION INSTRUCTIONS v1.0

50 TO 60 INSTALLATION INSTRUCTIONS v1.0 PLEASE READ Thank you for purchasing The TV Shield. Please read the following, before starting the installation process. UYou will need to unscrew the ten (10) black

50 TO 60 INSTALLATION INSTRUCTIONS v1.0 PLEASE READ Thank you for purchasing The TV Shield. Please read the following, before starting the installation process. UYou will need to unscrew the ten (10) black

MODEL T-4 TRENCHER. Operators Manual

DO NOT THROW AWAY IMPORTANT MANUAL MODEL TRENCHER Operators Manual P.O.BOX 290 San Bernardino, CA. 92402 Phone (909) 478-5700 (800) 922-4680 Fax (909) 478-5710 E-mail: [email protected] www.groundhoginc.com

DO NOT THROW AWAY IMPORTANT MANUAL MODEL TRENCHER Operators Manual P.O.BOX 290 San Bernardino, CA. 92402 Phone (909) 478-5700 (800) 922-4680 Fax (909) 478-5710 E-mail: [email protected] www.groundhoginc.com

FJ2. 2 Ton Trolley Floor Jack Assembly & Operating Instructions

FJ2 2 Ton Trolley Floor Jack Assembly & Operating Instructions READ ALL INSTRUCTIONS AND WARNINGS BEFORE USING THIS PRODUCT. This manual provides important information on proper operation & maintenance.

FJ2 2 Ton Trolley Floor Jack Assembly & Operating Instructions READ ALL INSTRUCTIONS AND WARNINGS BEFORE USING THIS PRODUCT. This manual provides important information on proper operation & maintenance.

UV100A Ultraviolet Air Treatment System

UV100A Ultraviolet Air Treatment System INSTALLATION INSTRUCTIONS APPLICATION When installed in forced air heating and cooling systems, the UV100A Ultraviolet Air Treatment System kills airborne microorganism

UV100A Ultraviolet Air Treatment System INSTALLATION INSTRUCTIONS APPLICATION When installed in forced air heating and cooling systems, the UV100A Ultraviolet Air Treatment System kills airborne microorganism

Assembly and Usage Instructions

Assembly and Usage Instructions A Product 5885 West Van Horn Tavern Road Columbia, MO 65203 www.caldwellshooting.com Instruction #1001667 Limited Warranty Every Caldwell product is warrantied to be free

Assembly and Usage Instructions A Product 5885 West Van Horn Tavern Road Columbia, MO 65203 www.caldwellshooting.com Instruction #1001667 Limited Warranty Every Caldwell product is warrantied to be free

Awning Instructions. Standard Manual 1.5m to 4.5m

Awning Instructions Standard Manual 1.5m to 4.5m English Standard Manual Instructions Contents Warning 1.5m 3.0m Awnings 4 x Expansion bolts (2 per bracket)** 2 x brackets 1 x Awning 1 x Winder handle

Awning Instructions Standard Manual 1.5m to 4.5m English Standard Manual Instructions Contents Warning 1.5m 3.0m Awnings 4 x Expansion bolts (2 per bracket)** 2 x brackets 1 x Awning 1 x Winder handle

Convertible Top Hydraulic Cylinder Removal Manual for W124 E-Class Convertibles 1993-1995 Models 300CE (1993) and E320 (1994-1995)

Convertible Top Hydraulic Cylinder Removal Manual for W124 E-Class Convertibles 1993-1995 Models 300CE (1993) and E320 (1994-1995) Written by Samit Ghosh with picture material from vexed of benzworld.org

Convertible Top Hydraulic Cylinder Removal Manual for W124 E-Class Convertibles 1993-1995 Models 300CE (1993) and E320 (1994-1995) Written by Samit Ghosh with picture material from vexed of benzworld.org

Good Manufacturing Practices for the Production of Packaging Inks formulated for use on the non food contact surfaces of food packaging and articles

Good Manufacturing Practices for the Production of Packaging Inks formulated for use on the non food contact surfaces of food packaging and articles intended to come into contact with food October 2005

Good Manufacturing Practices for the Production of Packaging Inks formulated for use on the non food contact surfaces of food packaging and articles intended to come into contact with food October 2005

Reinforced seam. Topstitching. 1.1.3 Straight stitch reverse Sew continuous reverse with strong tie-off.

Stitch overview Utility es Stitch Stitch number Name Description 1.1.1 Straight For seaming and toping. Select from 37 different needle positions. Note: This makes a stronger tie-off than 2.1.1. 1.1.2

Stitch overview Utility es Stitch Stitch number Name Description 1.1.1 Straight For seaming and toping. Select from 37 different needle positions. Note: This makes a stronger tie-off than 2.1.1. 1.1.2

pottery barn kids MADELINE BUNK BED

pottery barn kids MADELINE BUNK BED! WARNING: Failure to follow these warnings and assembly instructions could result in serious injury or death. To help prevent serious or fatal injuries from entrapment

pottery barn kids MADELINE BUNK BED! WARNING: Failure to follow these warnings and assembly instructions could result in serious injury or death. To help prevent serious or fatal injuries from entrapment

DETACHABLE WINDSHIELD AND DOCKING HARDWARE KIT

-J00 REV. 00-- DETACHABLE WINDSHIELD AND DOCKING HARDWARE KIT GENERAL Kit Number -A, 0-, -, 0-, -, - 0, -0 Models These kits fit and later FXST, FXSTB, FXSTC, and and later FXDWG Harley-Davidson model

-J00 REV. 00-- DETACHABLE WINDSHIELD AND DOCKING HARDWARE KIT GENERAL Kit Number -A, 0-, -, 0-, -, - 0, -0 Models These kits fit and later FXST, FXSTB, FXSTC, and and later FXDWG Harley-Davidson model

Searching, screening and confiscation. Advice for headteachers, school staff and governing bodies

Searching, screening and confiscation Advice for headteachers, school staff and governing bodies February 2014 Contents Summary 3 About this departmental advice 3 Expiry or review date 3 Who is this advice

Searching, screening and confiscation Advice for headteachers, school staff and governing bodies February 2014 Contents Summary 3 About this departmental advice 3 Expiry or review date 3 Who is this advice

CI SfB. (4-) Nn2. Onduline. Mini Profile. Onduline Garden Roof Range. Onduline Building Products Ltd

CI SfB (4-) Nn2 Onduline Mini Profile Onduline Garden Roof Range Onduline Building Products Ltd Onduline Garden Roof Range Onduline Mini Profile The new Onduline Mini Profile sheets have been designed

CI SfB (4-) Nn2 Onduline Mini Profile Onduline Garden Roof Range Onduline Building Products Ltd Onduline Garden Roof Range Onduline Mini Profile The new Onduline Mini Profile sheets have been designed

15 Training. 15.1 Public education on hazards linked to health-care waste

Training 15 Training 15.1 Public education on hazards linked to health-care waste Promotion of the appropriate handling and disposal of medical waste is important for community health, and every member

Training 15 Training 15.1 Public education on hazards linked to health-care waste Promotion of the appropriate handling and disposal of medical waste is important for community health, and every member

OWNER S MANUAL FOR PROFESSIONAL POPCORN MACHINE

OWNER S MANUAL FOR PROFESSIONAL POPCORN MACHINE Model Numbers 1911-4 OZ POPPER THEATER POP 4 CONTEMPO POP 4 1104110 (120 volts) 1104210 (120 volts) 1104220 (120 volts) 1204110 (230 volts) 1204210 (230

OWNER S MANUAL FOR PROFESSIONAL POPCORN MACHINE Model Numbers 1911-4 OZ POPPER THEATER POP 4 CONTEMPO POP 4 1104110 (120 volts) 1104210 (120 volts) 1104220 (120 volts) 1204110 (230 volts) 1204210 (230

User Installation Guide

Careline Alarm User Installation Guide 1.1 IMPORTANT INFORMATION The user s telephone MUST BE connected to the Reach TEL socket - a double adapter on the incoming line must not be used. If the user has

Careline Alarm User Installation Guide 1.1 IMPORTANT INFORMATION The user s telephone MUST BE connected to the Reach TEL socket - a double adapter on the incoming line must not be used. If the user has

Curtain Guards Made of PVC and designed to protect the operator from the risk of airborne chips or tool fragments.

Two General Safety Rule for CNC Machines Never operate a CNC machine without proper training or consulting the specific operator's manual for that particular machine and control type. Never attempt to

Two General Safety Rule for CNC Machines Never operate a CNC machine without proper training or consulting the specific operator's manual for that particular machine and control type. Never attempt to

MODEL T200-F18 MODEL T125-F18 Finish Nailers

P MODEL T200-F18 MODEL T125-F18 Finish Nailers IMPORTANT! DO NOT DESTROY It is the customer s responsibility to have all operators and service personnel read and understand this manual. OPERATING MANUAL

P MODEL T200-F18 MODEL T125-F18 Finish Nailers IMPORTANT! DO NOT DESTROY It is the customer s responsibility to have all operators and service personnel read and understand this manual. OPERATING MANUAL

ALVERNIA UNIVERSITY OSHA REGULATION: 29 CFR 1910.147 THE CONTROL OF HAZARDOUS ENERGY (LOCKOUT / TAGOUT) SECTION: 2400

OSHA REGULATION: 29 CFR 90.7 THE CONTROL OF HAZARDOUS ENERGY (LOCKOUT / TAGOUT) DATE: 0/5/2008 DATE: /2/202 A. POLICY. This procedure follows requirements set forth in 29 CFR 90.7. 2. It is the policy

OSHA REGULATION: 29 CFR 90.7 THE CONTROL OF HAZARDOUS ENERGY (LOCKOUT / TAGOUT) DATE: 0/5/2008 DATE: /2/202 A. POLICY. This procedure follows requirements set forth in 29 CFR 90.7. 2. It is the policy

Basic Spring Motor Roller Shades

Comprehensive Roller Shade Installation Guide Basic Spring Motor Roller Shades ATTENTION!!! READ CAREFULLY! This shade has a reliable long-lasting Spring Motor. The Spring Motor must have proper tension

Comprehensive Roller Shade Installation Guide Basic Spring Motor Roller Shades ATTENTION!!! READ CAREFULLY! This shade has a reliable long-lasting Spring Motor. The Spring Motor must have proper tension

How to Make A Quick & Easy Tabard or T-Tunic by Vaargard Malorius v1.0

You will need the following supplies to create a single tabard or t-tunic that hangs approximately to mid-thigh on a person about 6 tall. 2 1/2 yards material 1 Spool of thread that matches material color

You will need the following supplies to create a single tabard or t-tunic that hangs approximately to mid-thigh on a person about 6 tall. 2 1/2 yards material 1 Spool of thread that matches material color

Sumitomo Electric Wiring Systems, Inc. Part Identification and Labeling Requirements

1.0 INTRODUCTION These specifications provide guidelines for printing and applying a Shipping/Parts Identification label. Note: In this document, the word must indicates a requirement and the word should

1.0 INTRODUCTION These specifications provide guidelines for printing and applying a Shipping/Parts Identification label. Note: In this document, the word must indicates a requirement and the word should

Welcome to the safe@work Retail Module.

Welcome to the safe@work Retail Module. Have you read the General Module, completed the test and printed your safe@work General Award of Attainment? The Retail Module should be done AFTER the General Module.

Welcome to the safe@work Retail Module. Have you read the General Module, completed the test and printed your safe@work General Award of Attainment? The Retail Module should be done AFTER the General Module.

Food Safety and Quality Management System

Introduction The company has planned, established, documented and implemented a food safety and quality management system for the site, which is maintained in order to continually improve its effectiveness

Introduction The company has planned, established, documented and implemented a food safety and quality management system for the site, which is maintained in order to continually improve its effectiveness

ProTurn Power Turn Belts, Merge Table Belts

ProTurn Power Turn Belts, Merge Table Belts WHAT CAN WE OFFER? POWER TURN REPLACEMENT BELTS FROM BELTSERVICE In the case of conveyors, sometimes the most direct route isn t a straight line. In these situations,

ProTurn Power Turn Belts, Merge Table Belts WHAT CAN WE OFFER? POWER TURN REPLACEMENT BELTS FROM BELTSERVICE In the case of conveyors, sometimes the most direct route isn t a straight line. In these situations,

Portable Ladder Safety

Portable Ladder Safety Agenda Importance of Ladder Safety An Approved Ladder Controlling Hazards Inspecting the Ladder Set Up Use Importance of Ladder Safety Any fall can be serious, and a fall from the

Portable Ladder Safety Agenda Importance of Ladder Safety An Approved Ladder Controlling Hazards Inspecting the Ladder Set Up Use Importance of Ladder Safety Any fall can be serious, and a fall from the

SAFETY AND HEALTH PROGRAM

PROGRAM NUMBER NO. PAGES 05-005 10 REVISION ISSUE DATE Revision 2 11/1/2005 SAFETY AND HEALTH PROGRAM Confined Space Entry 1.0 INTRODUCTION Confined Space Entry is a serious workplace hazard, capable of

PROGRAM NUMBER NO. PAGES 05-005 10 REVISION ISSUE DATE Revision 2 11/1/2005 SAFETY AND HEALTH PROGRAM Confined Space Entry 1.0 INTRODUCTION Confined Space Entry is a serious workplace hazard, capable of

Weighted Pincushion Organizer

Weighted Pincushion Organizer This sturdy pincushion has plenty of space to store pins and a wool felt strip for your needles. The hanging pocket is a perfect place for storing easily-misplaced tools like

Weighted Pincushion Organizer This sturdy pincushion has plenty of space to store pins and a wool felt strip for your needles. The hanging pocket is a perfect place for storing easily-misplaced tools like

WASSCE / WAEC CLOTHING AND TEXTILES SYLLABUS WWW.LARNEDU.COM

WASSCE / WAEC CLOTHING AND TEXTILES SYLLABUS WWW.LARNEDU.COM Visit www.larnedu.com for WASSCE / WAEC syllabus on different subjects and more great stuff to help you ace the WASSCE in flying colours. 1.

WASSCE / WAEC CLOTHING AND TEXTILES SYLLABUS WWW.LARNEDU.COM Visit www.larnedu.com for WASSCE / WAEC syllabus on different subjects and more great stuff to help you ace the WASSCE in flying colours. 1.

HSC 2001 - Industrial Technology Band 4/5 INDUSTRIAL TECHNOLOGY FOLIO

Statement of Intent I intend to construct a slim boy which will suit my needs and will be compatible with my furniture in my bedroom in my house. This will be very handy and useful to everyone in my home.

Statement of Intent I intend to construct a slim boy which will suit my needs and will be compatible with my furniture in my bedroom in my house. This will be very handy and useful to everyone in my home.

3 WATT LED SPOTLIGHT Model No. SLM - 3801

3 WATT LED SPOTLIGHT Model No. SLM - 3801 OWNER'S MANUAL Customer Service Tel: 1-800-268-3319 Superex Canada Ltd, Toronto,M2H 3B8 Made in China Table of Contents A). Important Safety Instructions B). Charging

3 WATT LED SPOTLIGHT Model No. SLM - 3801 OWNER'S MANUAL Customer Service Tel: 1-800-268-3319 Superex Canada Ltd, Toronto,M2H 3B8 Made in China Table of Contents A). Important Safety Instructions B). Charging

Electronic Bid Submission Supplier Guide

Electronic Bid Submission Supplier Guide Canadian Public Tenders Agencies, Crown and Private Corporations Table of Contents 1 Electronic Bid Submission Check List... 2 2 Frequently Asked Questions... 2

Electronic Bid Submission Supplier Guide Canadian Public Tenders Agencies, Crown and Private Corporations Table of Contents 1 Electronic Bid Submission Check List... 2 2 Frequently Asked Questions... 2

LOCK-OUT / TAG-OUT SAFETY TRAINING

LOCK-OUT / TAG-OUT SAFETY TRAINING Introduction Welcome to Lock-out Tag-out Training "So I m on the job one day, doing some repair on a cutting machine.replacing a guide on the table. Pretty routine everything

LOCK-OUT / TAG-OUT SAFETY TRAINING Introduction Welcome to Lock-out Tag-out Training "So I m on the job one day, doing some repair on a cutting machine.replacing a guide on the table. Pretty routine everything

Best Methods for Safe Hipot Testing

Best Methods for Safe Hipot Testing When working with electrical safety test equipment, instruments that output potentially dangerous voltages and currents, it is always important to regular review and

Best Methods for Safe Hipot Testing When working with electrical safety test equipment, instruments that output potentially dangerous voltages and currents, it is always important to regular review and

Supply Chain Security Audit Tool - Warehousing/Distribution

Supply Chain Security Audit Tool - Warehousing/Distribution This audit tool was developed to assist manufacturer clients with the application of the concepts in the Rx-360 Supply Chain Security White Paper:

Supply Chain Security Audit Tool - Warehousing/Distribution This audit tool was developed to assist manufacturer clients with the application of the concepts in the Rx-360 Supply Chain Security White Paper:

Caboose Too Rear Seat Instruction Manual 0090X & 0091X Series

Caboose Too Rear Seat Instruction Manual 0090X & 0091X Series Joovy 2919 Canton Street Dallas, TX 75226 (877) 456-5049 Fax: (214) 761-1774 Email: [email protected] Web Site: www.joovy.com ! WARNING

Caboose Too Rear Seat Instruction Manual 0090X & 0091X Series Joovy 2919 Canton Street Dallas, TX 75226 (877) 456-5049 Fax: (214) 761-1774 Email: [email protected] Web Site: www.joovy.com ! WARNING

OLD BRICK ORIGINALS KILN-FIRED THIN BRICK VENEER Installation Guide. GeneralShale.com

OLD BRICK ORIGINALS KILN-FIRED THIN BRICK VENEER Installation Guide GeneralShale.com OLD BRICK ORIGINALS THIN BRICK VENEER Page 2 INTRODUCTION Check local building codes for proper installation guidelines

OLD BRICK ORIGINALS KILN-FIRED THIN BRICK VENEER Installation Guide GeneralShale.com OLD BRICK ORIGINALS THIN BRICK VENEER Page 2 INTRODUCTION Check local building codes for proper installation guidelines

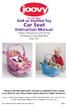

Just-Like-Mine! Doll or Stuffed Toy. Car Seat. Instruction Manual. These instructions are for the following Joovy Style # s: 002, 003

Just-Like-Mine! Doll or Stuffed Toy Car Seat Instruction Manual These instructions are for the following Joovy Style # s: 002, 003 Please read this instruction manual completely before using your doll

Just-Like-Mine! Doll or Stuffed Toy Car Seat Instruction Manual These instructions are for the following Joovy Style # s: 002, 003 Please read this instruction manual completely before using your doll

Housekeeping Audit Check Sheet for Warehouse (Refer SOP QMS-105)

Area Audited Audit Date Week Wk1 Wk2 Wk3 Wk4 Office Documentation stored appropriately Contact lists near phones are clearly displayed, current and easily accessible. All personal items are stored in lockers.

Area Audited Audit Date Week Wk1 Wk2 Wk3 Wk4 Office Documentation stored appropriately Contact lists near phones are clearly displayed, current and easily accessible. All personal items are stored in lockers.

section 5 machine guarding and lockout

section machine guarding and lockout This section covers ways to physically protect people working in and around machinery. It includes information on: machinery guards lockout systems emergency stop confined

section machine guarding and lockout This section covers ways to physically protect people working in and around machinery. It includes information on: machinery guards lockout systems emergency stop confined

Cleaning and Support Services / Cleaning Services Supervision National Occupational Standards

Cleaning and Support Services / Cleaning Services Supervision National Occupational Standards Contents C1 02 Maintain Personal Hygiene Standards when Cleaning... 3 C1 03 Do your job in a customer friendly

Cleaning and Support Services / Cleaning Services Supervision National Occupational Standards Contents C1 02 Maintain Personal Hygiene Standards when Cleaning... 3 C1 03 Do your job in a customer friendly

WEEKLY SAFETY MEETING All Euramax Subsidiaries HOUSEKEEPING. Safety Meeting Contents. Meeting Notice. Leaders Guide. Employee Handout.

Safety Meeting Contents Meeting Notice Leaders Guide Employee Handout Employee Quiz Meeting Sign-In Sheet Employee Puzzle PRIOR TO THE WEEKLY MEETING: - Post the meeting notice by the timeclock - Read

Safety Meeting Contents Meeting Notice Leaders Guide Employee Handout Employee Quiz Meeting Sign-In Sheet Employee Puzzle PRIOR TO THE WEEKLY MEETING: - Post the meeting notice by the timeclock - Read

Sewing and braiding Coil headed pins

Coil headed pins Coil headed pins pins were very important in medieval times, and were made from bone, fish bones, wood, thorns, ivory, shell and metal. Pins were used to hold fabric together to be sewn,

Coil headed pins Coil headed pins pins were very important in medieval times, and were made from bone, fish bones, wood, thorns, ivory, shell and metal. Pins were used to hold fabric together to be sewn,

Homeowner s Handbook

Homeowner s Handbook Congratulations on buying your new home This booklet will provide you with important information on the warranty cover for your new home which has been arranged by your developer.

Homeowner s Handbook Congratulations on buying your new home This booklet will provide you with important information on the warranty cover for your new home which has been arranged by your developer.

SCREAMIN' EAGLE "HEAVY BREATHER" PERFORMANCE AIR CLEANER KIT

REV. 05-04- SCREAMIN' EAGLE "HEAVY BREATHER" PERFORMANCE AIR CLEANER KIT GENERAL Kit Numbers 95-08B, 9006-09B, 876-0A Models For model fitment information, see the P&A Retail Catalog or the Parts and Accessories

REV. 05-04- SCREAMIN' EAGLE "HEAVY BREATHER" PERFORMANCE AIR CLEANER KIT GENERAL Kit Numbers 95-08B, 9006-09B, 876-0A Models For model fitment information, see the P&A Retail Catalog or the Parts and Accessories

Why is lighting in the workplace important?

OSH Brief No. 3c Why is lighting in the workplace important? From the workers perspective, poor lighting at work can lead to eye strain, fatigue, headaches, stress and accidents. On the other hand, too

OSH Brief No. 3c Why is lighting in the workplace important? From the workers perspective, poor lighting at work can lead to eye strain, fatigue, headaches, stress and accidents. On the other hand, too